The Rise of Nitro Cold Brew: A Technological Revolution

The nitro cold brew coffee craze, once a niche curiosity for coffee aficionados, has exploded onto the mainstream, becoming a fixture in cafes, bars, and even restaurants worldwide. This meteoric rise isn’t just a fleeting trend; it signifies a fundamental shift in consumer preferences towards smoother, richer, and more versatile coffee experiences. The surge in popularity has ignited a wave of innovation in nitro cold brew technology, providing businesses with cutting-edge tools to not only elevate their offerings but also streamline operations and capitalize on this burgeoning market.

From independent coffee shops to large-scale beverage chains, businesses are recognizing the potential of nitro cold brew to attract new customers and boost profitability. The allure of nitro cold brew lies in its unique characteristics. The infusion of nitrogen gas creates a velvety smooth texture reminiscent of draft beer, complete with a cascading visual effect that elevates the coffee-drinking experience. This creamy texture, coupled with the naturally sweeter profile of cold brew, appeals to a broader audience, including those who might find traditional iced coffee too bitter or acidic. “The nitrogen infusion creates a textural transformation that is truly captivating,” says Sarah Miller, a leading barista and coffee consultant. “It’s not just about the taste; it’s about the entire sensory experience.” This enhanced sensory experience translates to a premium product that justifies a higher price point, increasing profit margins for businesses.

The innovation extends beyond the brewing process itself. Advanced dispensing systems, featuring precision pouring taps and sophisticated keg systems, are crucial for maintaining the quality and consistency of nitro cold brew. These systems minimize waste, ensure a perfect pour every time, and preserve the delicate nitrogen infusion, guaranteeing a consistent experience for the customer. Furthermore, these technological advancements contribute to operational efficiency, reducing labor costs and streamlining workflows. For example, automated dispensing systems can free up baristas to focus on other tasks, improving overall productivity.

This combination of enhanced product quality and operational efficiency makes investing in nitro cold brew technology a compelling proposition for businesses of all sizes. The rise of nitro cold brew also intersects with the growing consumer demand for innovative and customizable beverage options. The versatility of nitro cold brew allows for creative flavor combinations and additions, such as flavored syrups, spices, and even dairy or non-dairy alternatives. This adaptability provides businesses with opportunities to experiment with unique signature drinks and cater to a wider range of tastes, further driving customer engagement and sales.

This trend towards customization and premiumization within the beverage industry perfectly aligns with the elevated experience offered by nitro cold brew, solidifying its position as a key driver of growth in the coffee market. Finally, the increasing focus on sustainability within the food and beverage industry is influencing the development of eco-friendly nitro cold brew equipment and packaging solutions. Businesses are seeking ways to minimize their environmental footprint, and manufacturers are responding with innovative technologies that reduce waste and conserve resources. This commitment to sustainability not only appeals to environmentally conscious consumers but also contributes to long-term cost savings for businesses, creating a win-win scenario for both the environment and the bottom line.

Brewing Innovations: Exploring the Latest Nitro Coffee Machines

The nitro cold brew revolution has ushered in a new era of coffee equipment, transforming how cafes and businesses operate and serve this increasingly popular beverage. Today’s market offers a diverse array of nitro coffee brewing machines, each designed with unique features and capabilities to meet the specific needs and budgets of various businesses. From high-capacity systems engineered for large-scale production in bustling coffee shops to compact, user-friendly models ideal for smaller cafes or restaurants venturing into the nitro cold brew arena, the options are plentiful.

Choosing the right equipment is a crucial business decision, impacting efficiency, product quality, and ultimately, profitability. Key features to consider include brew time, crucial for maximizing output during peak hours; precise temperature control, ensuring consistent flavor profiles; and automation capabilities, streamlining workflows and minimizing barista intervention. One of the most significant advancements in nitro brewing technology is the integration of programmable automation. High-end machines allow baristas to pre-set brew parameters like coffee-to-water ratio, nitrogen infusion levels, and even chilling times, ensuring consistent quality across multiple batches and minimizing potential human error.

This level of control is particularly beneficial for businesses with high turnover or those looking to maintain a standardized flavor profile across multiple locations. For example, some automated systems can integrate with inventory management software, tracking coffee bean usage and automatically reordering when supplies run low, further optimizing operations and reducing waste. This integration of technology not only streamlines the brewing process but also provides valuable data insights that can inform business decisions. Beyond automation, innovation in brewing technology also focuses on enhancing the sensory experience of nitro cold brew.

Some machines utilize advanced filtration systems that remove unwanted sediment and oils, resulting in a cleaner, smoother, and more visually appealing final product. Others incorporate features like adjustable nitrogen infusion levels, allowing baristas to fine-tune the texture and mouthfeel of the beverage, creating anything from a light and airy cascade to a thick and creamy head. This level of customization empowers businesses to cater to diverse customer preferences and experiment with unique flavor profiles, driving innovation within the nitro cold brew category.

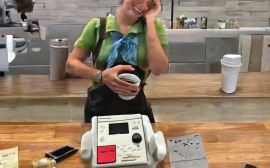

Moreover, manufacturers are increasingly prioritizing sustainability in their designs, incorporating energy-efficient components and utilizing recyclable materials, appealing to environmentally conscious businesses and consumers. For smaller cafes and businesses, compact nitro cold brew systems offer an accessible entry point into this burgeoning market. These smaller footprint machines often feature simplified controls and user-friendly interfaces, making them ideal for businesses with limited counter space or those new to nitro brewing. While they may not offer the same high-volume output as their larger counterparts, these compact systems still deliver high-quality nitro cold brew, enabling smaller businesses to compete in this increasingly competitive market.

Furthermore, many of these smaller systems are designed with portability in mind, making them suitable for catering events, pop-up shops, and other mobile operations. This flexibility allows businesses to expand their reach and introduce nitro cold brew to new audiences. Ultimately, the choice of nitro brewing equipment depends on a variety of factors, including business size, budget, desired output, and required level of automation. By carefully considering these factors and understanding the latest innovations in brewing technology, businesses can make informed decisions that maximize their investment and position them for success in the dynamic world of nitro cold brew.

Nitrogen Infusion Techniques: Inline vs. Post-Brew

Nitrogen infusion is the heart of nitro cold brew, giving it the signature cascading visual effect and luxuriously creamy texture that sets it apart. This process, essentially dissolving nitrogen gas into the coffee, transforms the drinking experience. Two primary methods achieve this infusion: inline and post-brew. Understanding the nuances of each is crucial for coffee businesses seeking to optimize their nitro cold brew offerings. Inline infusion introduces nitrogen during the brewing process itself. This method, often utilizing specialized brewing equipment, allows for greater integration of the nitrogen into the coffee, resulting in a smoother, more integrated texture.

For high-volume coffee shops and cafes, inline systems offer efficiency, streamlining the process and reducing handling time. However, the initial investment in specialized equipment can be a barrier for smaller businesses. Furthermore, adjusting nitrogen levels for different coffee profiles requires technical expertise, demanding a higher level of barista training. Post-brew infusion, as the name suggests, adds nitrogen after the coffee has been brewed. This method offers greater flexibility, particularly for businesses with existing cold brew setups.

Utilizing devices such as nitrogen tanks and dispensing systems, baristas can infuse nitrogen into pre-brewed batches. This method allows for experimentation with different nitrogen levels and coffee profiles, catering to diverse customer preferences. Post-brew offers a lower barrier to entry for smaller cafes, as the equipment investment is generally less substantial than inline systems. However, it can be more labor-intensive, requiring separate infusion and dispensing steps. Maintaining consistent nitrogen levels across batches also necessitates careful monitoring by the barista.

From a business perspective, the choice between inline and post-brew impacts operational efficiency and cost-effectiveness. Inline systems, while requiring a higher initial investment, can reduce labor costs in high-volume settings. Post-brew, with its lower upfront cost, offers flexibility but demands more hands-on management. The beverage industry is continuously innovating, and nitrogen infusion technology is no exception. New dispensing systems and brewing equipment are emerging, giving businesses more options for customizing their nitro cold brew programs.

Coffee shop owners must weigh these factors carefully, considering their scale of operation, budget, and desired level of control over the final product. The flavor profile of nitro cold brew is also influenced by the infusion method. Inline infusion, with its thorough integration of nitrogen, can subtly mute the coffee’s acidity, resulting in a sweeter, more chocolatey flavor profile. This method is ideal for showcasing coffees with naturally lower acidity, enhancing their inherent sweetness. Post-brew infusion, on the other hand, allows for more pronounced coffee flavors to shine through, as the nitrogen integration is less complete.

This method is well-suited for highlighting coffees with brighter acidity and complex flavor profiles. Ultimately, the choice between inline and post-brew depends on the desired flavor outcome and the specific characteristics of the coffee being used. Finally, the texture of nitro cold brew, arguably its most defining characteristic, is directly impacted by nitrogen infusion. Both methods generate the characteristic creamy texture, but with subtle variations. Inline infusion tends to produce a denser, more velvety texture due to the complete integration of nitrogen during brewing. Post-brew infusion, while still delivering a creamy mouthfeel, can result in a slightly lighter, more aerated texture. These textural nuances can significantly influence the overall sensory experience of drinking nitro cold brew, adding another layer of complexity to the decision-making process for coffee businesses.

Dispensing Innovations: Maintaining Quality and Consistency

Innovative dispensing systems are critical for maintaining the quality and consistency of nitro cold brew, directly impacting both customer satisfaction and operational efficiency within the coffee shop and broader beverage industry. Precision pouring taps, a significant advancement in coffee technology, minimize waste by controlling the flow rate and preventing over-pouring, ensuring each serving is consistent in volume and presentation. This precision is not merely aesthetic; it directly affects the perceived value and flavor profile of the beverage, as the correct ratio of coffee to nitrogen is essential for the signature creamy texture and cascading effect that define a well-made nitro cold brew.

These taps often incorporate features like adjustable flow settings and ergonomic designs, making them user-friendly for baristas and contributing to a smoother, faster service process during peak hours. Advanced keg systems represent another crucial innovation, extending the shelf life and preserving the delicate flavors of nitro cold brew. Unlike traditional coffee dispensing methods, these systems are designed to maintain the ideal pressure and temperature, preventing oxidation and flavor degradation. High-quality, food-grade kegs, often equipped with nitrogen regulators and pressure gauges, ensure the beverage remains fresh for longer periods, reducing product waste and maximizing profitability for businesses.

Furthermore, some systems incorporate smart technology, allowing for remote monitoring of keg levels and temperature, providing valuable data insights for inventory management and quality control. This technology-driven approach is essential for maintaining a consistent product experience, particularly in high-volume settings or for businesses with multiple locations. The integration of these dispensing technologies also has a profound impact on the operational side of the business. By minimizing waste and ensuring consistent pours, businesses can reduce costs associated with product loss and improve overall profitability.

The efficiency gains from precision taps and advanced keg systems also translate to faster service times, allowing baristas to serve more customers during peak hours. This is especially crucial for cafes and coffee shops operating in high-traffic locations or during busy periods. Moreover, the consistency provided by these systems allows for better forecasting and inventory management, further streamlining operations and reducing the risk of running out of product or overstocking. The investment in these technologies is not just about improving the product; it’s about enhancing the entire business model.

Beyond the immediate benefits of waste reduction and improved consistency, these dispensing innovations are also driving the evolution of the nitro cold brew market. The ability to maintain product quality over longer periods has opened new avenues for businesses, such as offering pre-packaged nitro cold brew in cans or bottles, extending their reach beyond the traditional cafe setting. This expansion is further fueled by the development of portable dispensing systems, allowing businesses to offer nitro cold brew at events, catering services, and other off-site locations.

This increased accessibility and availability are contributing to the continued growth and popularity of nitro cold brew, solidifying its position as a significant player in the beverage industry. The technological advancements in dispensing are therefore not just supporting the current market but also actively shaping its future. Finally, the development of these dispensing technologies also aligns with the growing emphasis on sustainability within the food and beverage sector. By minimizing waste, reducing the need for single-use packaging, and ensuring efficient resource utilization, these systems contribute to a more environmentally responsible approach to coffee service.

The use of refillable kegs, coupled with precision pouring, reduces the overall carbon footprint associated with nitro cold brew production and distribution. As consumers become increasingly conscious of environmental issues, businesses that adopt these sustainable practices are likely to gain a competitive advantage and enhance their brand reputation. Therefore, the innovation in dispensing systems is not just about improving the quality and consistency of nitro cold brew; it’s also about creating a more sustainable and responsible business model within the coffee industry.

Case Studies: Real-World Success with Nitro Cold Brew Technology

The transformative impact of advanced nitro cold brew technology is evident in the success stories of businesses that have embraced these innovations. From increased sales and reduced waste to enhanced product consistency and elevated customer experiences, the benefits are substantial and far-reaching. For instance, a specialty coffee chain, known for its commitment to quality and innovation, reported a 20% surge in nitro cold brew sales following the integration of a new brewing and dispensing system.

This system, featuring automated nitrogen infusion and precision pouring taps, not only streamlined operations but also delivered a consistently smooth and creamy nitro cold brew, attracting new customers and boosting brand loyalty. The chain’s success underscores the business value of investing in cutting-edge coffee technology. In another compelling example, a small, independent cafe witnessed a significant reduction in product waste and a marked improvement in consistency after implementing a precision pouring tap. This seemingly small change minimized over-pouring and ensured each customer received a perfectly crafted nitro cold brew, enhancing customer satisfaction and optimizing profitability.

Beyond these individual examples, industry data further supports the positive impact of nitro cold brew technology on business performance. A recent market analysis revealed that cafes and coffee shops offering nitro cold brew experienced an average increase in overall beverage sales, demonstrating the growing consumer demand for this premium coffee experience. The report also highlighted the role of technology in meeting this demand efficiently and profitably. Furthermore, the adoption of advanced nitrogen infusion systems has enabled businesses to experiment with new flavor profiles and create signature nitro cold brew offerings, further differentiating themselves in a competitive market.

By precisely controlling nitrogen levels and infusion methods, baristas can fine-tune the texture and mouthfeel of their nitro cold brew, crafting unique and appealing beverages that cater to diverse consumer preferences. This level of customization not only enhances the customer experience but also positions businesses as innovators in the specialty coffee segment. Finally, the integration of sustainable practices within nitro cold brew technology is gaining traction, aligning with the growing consumer awareness of environmental responsibility. Businesses are increasingly adopting eco-friendly brewing equipment, reusable kegs, and compostable packaging solutions, minimizing their environmental footprint and appealing to environmentally conscious consumers. This commitment to sustainability not only benefits the planet but also enhances brand image and resonates with values-driven customers.

Future Trends: Sustainability and Automation

The future of nitro cold brew is brimming with potential, driven by a wave of innovation focused on sustainability, automation, and enhanced customer experiences. Sustainability is a key focus, with manufacturers developing eco-friendly brewing equipment and packaging solutions. This trend aligns with the growing consumer demand for environmentally conscious products and practices within the coffee industry. For instance, companies are exploring reusable kegs, compostable coffee pods for nitro brewing, and energy-efficient brewing systems to minimize their environmental footprint.

This shift towards sustainability not only benefits the planet but also enhances brand image and attracts environmentally conscious consumers, a growing segment of the coffee market. Furthermore, the move towards sustainable packaging, such as plant-based alternatives to traditional plastic cups, offers cafes a competitive edge while appealing to increasingly eco-minded customers. Several coffee shops are partnering with local recycling programs and implementing initiatives to reduce waste, further bolstering their commitment to sustainability. Automation is another area of significant innovation, with automated brewing and dispensing systems streamlining operations and reducing labor costs.

Automated systems can precisely control brewing parameters like temperature, brew time, and nitrogen infusion, ensuring consistent quality and reducing the reliance on highly skilled baristas for complex nitro cold brew preparation. This efficiency not only saves businesses money but also frees up staff to focus on customer service and other essential tasks. Imagine a cafe where a barista can initiate a perfect nitro cold brew pour with a single touch, then turn their attention to crafting latte art or engaging with customers.

This level of automation is becoming increasingly accessible, empowering even small cafes to offer high-quality nitro cold brew with greater efficiency. Furthermore, automated systems can track data on popular brews, peak demand times, and ingredient usage, providing valuable insights for inventory management and menu optimization. This data-driven approach helps businesses streamline their operations and make informed decisions to maximize profitability. Beyond sustainability and automation, the future of nitro cold brew also lies in personalized experiences.

Imagine customizable nitrogen levels, allowing customers to tailor the creaminess and texture of their beverage. This level of customization opens up new possibilities for flavor exploration and caters to individual preferences, further elevating the nitro cold brew experience. Furthermore, advancements in mobile ordering and payment systems allow customers to pre-order their customized nitro cold brew, pick it up at their convenience, and even earn loyalty points, enhancing convenience and fostering customer loyalty. As technology continues to evolve, we can anticipate even more innovative applications, such as smart dispensing systems that adjust nitrogen levels based on ambient temperature and humidity, ensuring a perfect pour every time, regardless of environmental conditions. These advancements will not only enhance the customer experience but also position nitro cold brew as a premium, customizable, and technologically advanced beverage option in the ever-evolving coffee landscape.